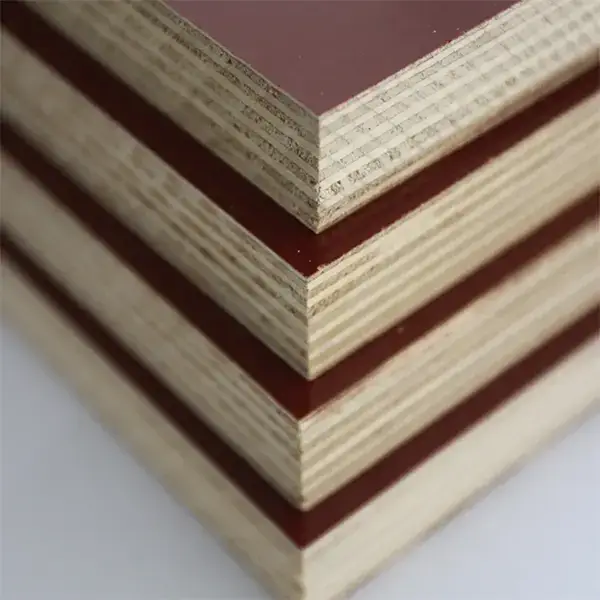

Red Film Faced Plywood

Advantages:

- Transference to concrete is set up very easily, so good for construction work.

- Waterproof, Wear-resistant, anti-cracking.

- After installation of concrete, the surface looks like a mirror. (The cement does not stick.)

- Environmentally friendly.

- It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time.

Essential Details

| Size: | 1220*2440mm or other size as per customer’s request | Feature: | Beautiful, moisture-proof |

| Material: | Wood Fiber | Melamine Colors: | Solid color,wood grain,etc. |

| Grade: | FIRST-CLASS, FIRST-CLASS | Core: | Pine Birch, as your requirement. |

| Delivery Time: | Within 20 days received deposit or original L/C at sight | Veneer Board Surface Finishing: | One-Sided Decoration |

| Usage: | Indoor | Application: | Office Building, Indoor, Furniture Decoration |

Tailoring for you

Superior Red Film Plywood

Experience Construction Excellence with Superior Red Film Plywood – Where Durability Meets Distinction.

Packaging & Delivery

| Selling Units: | Multiple of 400 | Gross weight per batch: | 16.000 kg |

| Package size per batch: | 1220X1220X0.02 cm | Picture Example: |  |

| Package Type: | Inner packing: Inside pallet is wrapped with a 0.20mm plastic bag Outer packing: Pallets are covered with 3mm package plywood or carton and then steel tapes for strengthening |

Lead Time

| Quantity(pieces) | 1 – 400000 | >400000 |

| Lead time (days) | 15 | To be negotiated |

Red Film Faced Shuttering Plywood: The Ultimate Choice for Demanding Construction Projects

When your construction project demands more than standard formwork materials, red film faced shuttering plywood stands out as the undisputed ultimate choice. This distinctive red panel is not just a symbol of performance but a critical investment for project success.

What Is Red Film Faced Shuttering Plywood?

Red film faced plywood is a high-performance variant of standard film faced plywood. Its key distinction lies in the tough, red phenolic resin film, which is typically thicker and denser, thermally fused onto a high-quality wood core. This structure enables it to withstand the most demanding construction conditions, including high humidity, heavy reinforcement, and high-pressure concrete pouring.

As a professional construction panel manufacturer, Plyboost produces red film faced shuttering plywood using selected wood cores and imported phenolic glue, ensuring every panel delivers consistent and exceptional performance.

Outstanding Advantages of Red Film Faced Plywood: Beyond Standard Black and Brown

Choosing red film faced shuttering plywood means investing in longer service life and lower cost per use for your project. Here are its key advantages:

Unmatched Reusability

This is its most notable advantage. Thanks to its enhanced film and robust core, high-quality red film faced plywood can achieve up to 50-60 reuses or even more, far exceeding standard film faced plywood (typically 20-30 reuses). For large, long-term projects, this translates directly into significant cost savings.Superior Wear and Impact Resistance

The red phenolic film surface offers exceptional hardness and abrasion resistance, effectively withstanding physical wear during installation, dismantling, and cleaning, as well as scratches from reinforcement bars.Perfect Concrete Finishing

Like all high-quality film faced panels, Plyboost’s red film faced shuttering plywood produces exceptionally smooth concrete surfaces. Its excellent release properties ensure concrete does not adhere to the panel, delivering consistent high-quality finishes after every use.Exceptional Moisture and Water Resistance

The enhanced film provides superior sealing, effectively preventing moisture penetration and avoiding core mold or delamination. This makes it particularly outstanding in concrete projects requiring extended curing times, with durability comparable to marine plywood designed for prolonged damp environments, while being more specialized for formwork applications.

Making an Informed Choice for Your Project: When to Use Red Film Faced Shuttering Plywood?

While standard film faced plywood is versatile, investing in red film faced shuttering plywood is a wise decision in the following scenarios:

Large Infrastructure Projects: Such as bridges, dams, and core tubes of high-rise buildings, where formwork reuse demands are extremely high.

Pre-mix Concrete Plants: Requiring durable panels capable of withstanding high-frequency use.

Projects with Extremely High Requirements for Concrete Surface Smoothness: Such as architectural concrete designs.

Pursuing Overall Project Cost Efficiency: Although the initial investment is higher, its remarkable reusability significantly reduces the cost per use.

Plyboost: Your Reliable Chinese Supplier for Red Film Faced Shuttering Plywood

At Plyboost, we understand the stringent requirements for material reliability in heavy-duty construction. Utilizing advanced production technology and strict quality control processes, we ensure every sheet of red film faced shuttering plywood we produce delivers the promised high performance.

As a manufacturer from China, we can offer you highly competitive pricing without compromising on quality. Our comprehensive product range, from premium red film faced plywood to cost-effective commercial plywood, as well as birch plywood and melamine mdf, meets all your needs, from structural to decorative applications.

Contact Plyboost today to request free samples and detailed technical specifications for our red film faced shuttering plywood. Experience its exceptional quality firsthand!

Related Products

Related blogs

An Analysis of the Advantages and Disadvantages of Different Edge Treatment Methods for Melamine Plywood

Melamine plywood, a material widely used in furniture manufacturing, interior decoration, and other fields, has

Additives Used in Plywood Glue: Functions and Benefits

Additives are essential in plywood glue formulations, enhancing the performance, durability, and environmental friendliness of

Synchro Plywood: A High-Quality Composite for Realistic Wood Finishes

What is Synchro Plywood? Synchro Plywood is an innovative composite material designed to emulate the

The 5 Best Kitchen Cabinet Materials: Pros and Cons

Choosing the right material for your kitchen cabinets is essential for both style and durability.

Kitchen Cabinet Fabrication: Plywood vs. Melamine Board

Choosing the right material for your kitchen cabinets is a critical decision that impacts the

Exploring the Versatility and Strength of the OSB Board

Oriented Strand Board (OSB) is transforming the construction landscape with its remarkable versatility, strength, and

What is Furniture board?

Furniture board, as the term implies, refers to a type of engineered wood product that

Understanding and Analysis of WPC Board vs Plywood

When deciding on materials for interior work in homes or offices, two of the most