Plywood & Eco-friendly board materials

Manufacturer since 1992

PLYBOOST helps you obtain cost-advantaged board materials and new marketing strategies. With over 30 years of deep experience in the industry, spanning two generations, PLYBOOST enables you to gain multidimensional market competitiveness and higher profits.

Custom specification service

Fully automatic factory

Cost advantage of industrial belt

Precision delivery & after-sales

China Plywood Factory

The following products can be customized according to your specifications.

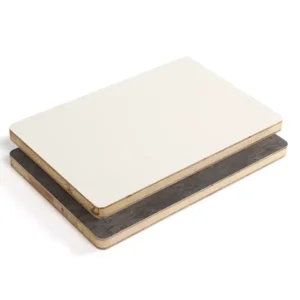

More competitive product: PET - G Plywood

What is PET - G?

PETG plywood typically refers to a type of plywood that has a surface or veneer made of PETG (Polyethylene Terephthalate Glycol) material. PETG is a transparent thermoplastic that is commonly used for its clarity, impact resistance, and ease of fabrication.

This type of plywood is often used in applications where a transparent or glossy surface is desired, such as in furniture manufacturing, cabinetry, signage, or decorative wall panels. PETG veneer plywood can offer a unique aesthetic while still providing the structural support and stability associated with traditional plywood.

Plywood Manufacturer - Choose Better Factory Price

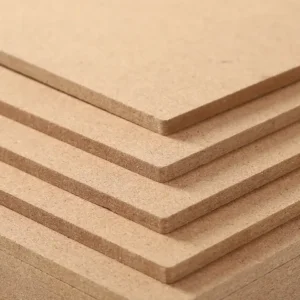

Wholesale full MDF/HDF

Wholesale full OSB/Particle Board

Wide custom options

for your unique plywood applications

Partner with Plyboost to become the most competitive plywood dealers.

Wide Custom Options

In the application field, there may be specific requirements, and we provide you with special and extensive customization options for sheet materials

Specification

We offer options of different specifications to ensure that you can accurately customize your products.

- Thickness 5-18mm

- Density: low density, medium density, high density

- Load-bearing performance: low-high

- Number of layers: 3, 5, 7, 8, 9, 10

- Hardness: low-high

Base material

Our customized solutions to produce plywood with different substrates to help ensure that they suit the products you need.

- Plywood substrate: Poplar, pine, birch, eucalyptus

- OSB substrate: Poplar, pine, eucalyptus

- Block board: Poplar, pine, eucalyptus, Chinese fir

Color & Finish

You have a wide range of color options to consider which will help you better position yourself in the market and bring in some unique pieces.

- Thousands of finishes are available

- There are many kinds of molds for texture: matte, highlight, skin feel, bump texture, etc

OEM

We are well aware that cost and quality are the core factors that OEM needs to balance most:

- Industrial output standard of automation equipment.

- Strict SOP production tracking

- Advantages of industrial belt to control the cost of raw materials

- 30 years of experience in cost control and process control

Others

You can also contact us directly for special application scenarios.

- Compression resistance

- Waterproof

- Fire prevention

Sourcing plywood & eco-friendly board materials from Plyboost.

For your costs and profits

In market competition, competition can greatly reduce your profits. Therefore, either we support you with lower prices, or we break through the competition with differentiated new products.

- Combine labor cost and process standardization to output to wholesalers at a lower price.

- Continuous innovation.

All new products must win in the Chinese competition and then be copied to our wholesalers.

For your quality

- In the industry, we have accumulated and selected a number of raw material suppliers, which can trace and control the output of high-quality materials.

- SOP management and production system standardization output.

For your delivery & after sales

- < 1000 sheets for 10-15 days

> 1000 tickets for 20-25 days - Service throughout the entire lifespan of your product.From confirming samples to technical services

Manufacturing plant for Plyboost

YOUR PRODUCTS ARE PRODUCED HERE

The factory covers an area of about 20000㎡ and is distributed in three areas, making full use of the cost advantage of the place of origin.

Standard SOP production process, so that every process of product production can accurately control quality.

Pre-delivery inspection & packaging

QC team will check the cargo piece by piece and test it in our lab. Testing report is issued to customers together with QC pictures including size, thickness, moisture content , edge treatment, package and etc. Loading will be done only after customer’s final permission.

Consult your plywood production expert from Plyboost

We help you avoid the pitfalls to deliver the quality and value your plywood & eco-friendly board need, on-time and on-budget.