Film Faced Plywood

Concrete formwork plywood

Plywood overlaid with a smooth coating for concrete formwork or shuttering

Concrete formwork plywood is one of our Plyboost factory main products.the Grade from finger jointed core to Full birch core.Re-using times can be from 2-50 times according to different raw materials. Film faced plywood advantages.

Attention to detail:Order production full quality exclusive supervisor tracking, SOP process accurately control

Customer service :Our team is always available to answer questions, provide advice, and address any concerns that our customers may have.

Product MOQ:1x20GP(Customized product reference details)

PAYMENT TERMS: T/T 30%deposit/LC

Essential Details

| Brand Name: | PLYBOOST | After-sale Service: | Online technical support |

| Project Solution Capability: | Graphic design | Place of Origin: | China |

| Grade: | FIRST-CLASS | Warranty | 1 Year |

| Formaldehyde Emission Standards: | E1 | Main Material: | Poplar |

| Core: | Poplar, hardwood, birch, pine, combi , and so on | Veneer Board Surface Finishing: | Double-Sided Decoration |

| Certification: | CE ISO9001 FSC CARB | Product name: | Film Faced Plywood |

| Moisture Content: | 8%~15% | Thickness: | 9-25mm or customize |

| Glue: | MR/E0/E1/E2/WBP/Melamine | Size: | 1220x2440mm, 1250x2500mm,915x1830mm |

| Advantage: | Waterproof Material | Application: | Poplar Pine Combi |

| MOQ | 1x20GP | Pament Terms: | T/T 30%deposit/LC |

Core

Finger Joint/Blockboard

Glue: WBP Melamine

Thickness: 12/15/18mm

Reuse: 2-4 times

Price: Cheap

Poplar

Glue: WBP Melamine

Thickness: 8/10/12/15/18mm

Reuse: 6-10 times

Price: Medium

Eucalyptus

Glue: WBP Melamine/Phenolic

Thickness: 12/15/18mm

Reuse: 10-15 times

Price: Premium

Film

Packaging & Delivery

Lead time:

| Quantity(pieces) | 1 – 1000 | 1001 – 5000 | 5001 – 10000 | >10000 |

| Lead time (days) | 3 | 7 | 15 | To be negotiated |

Tailoring for you

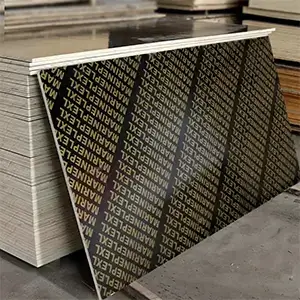

Concrete Formwork Plywood

we provide various sizes and specifications to meet your different needs

We know that you have been looking for the best price of the best price,

Product Name | Concrete Formwork Plywood | |

F/B | Black film, brown film,red film | |

Grade | Construntion grade(one/two time hot press) | |

Core | Poplar, hardwood, birch, pine, combi , and so on | |

Glue | mealmine and WBP E0 E1 E2 | |

Thickness | 9-25mm or customize | |

Specification | 1220x2440mm, 1250x2500mm,915x1830mm | |

Moisture Content | 8-10% | |

MOQ | 1x20GP | |

Usages | Can be widely used for building concrete, etc | |

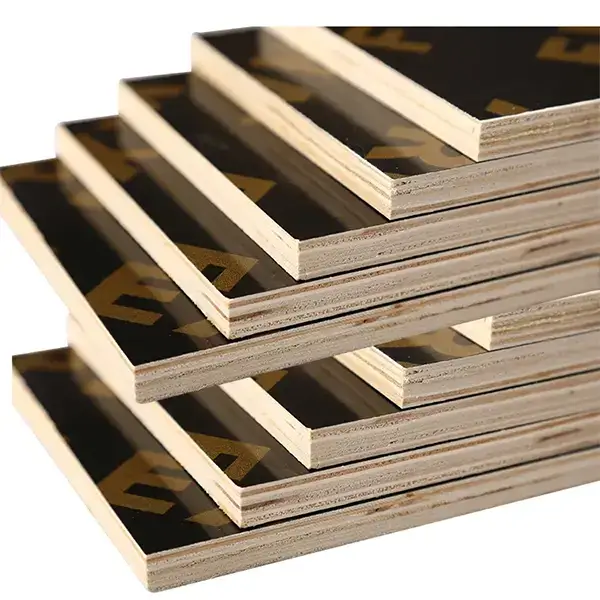

Cycle Life | About 20-30 repeated using times according to formwork application projects. | |

Bending Modules of Elasticty | Longitudinal | 9500Mpa |

Lateral | 7500Mpa | |

Bending Strength N/mm | Longitudinal | 85.1Mpa |

Lateral | 68.3Mpa | |

Product Display

Maximize efficiency and performance with film faced plywood for concrete formwork

What is film faced plywood (concrete formwork plywood)?

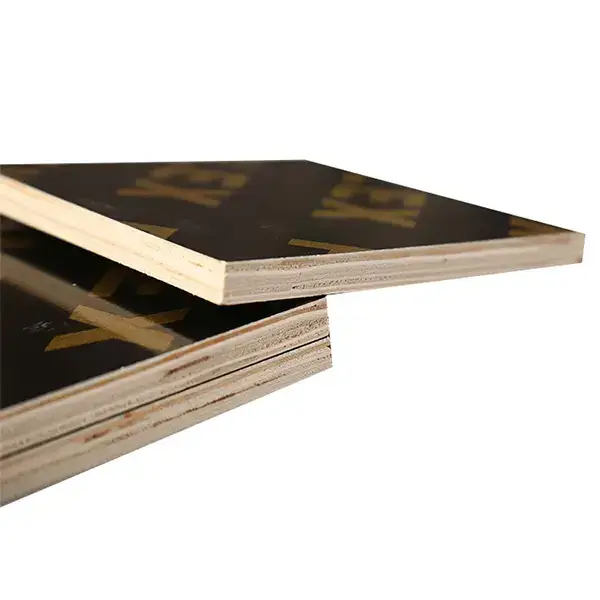

Film faced plywood, commonly known as concrete formwork plywood, is an engineered wood panel specifically designed for high-strength construction applications. Its core feature is a tough, phenolic resin-impregnated film thermally fused onto a high-quality core panel. This film provides unparalleled waterproof, moisture-resistant, and chemical-resistant properties, allowing it to withstand the alkaline environment and high pressure of wet concrete.

As a professional Chinese supplier of construction panels, every sheet of film faced plywood manufactured by Plyboost undergoes precision processing to ensure a smooth surface and sealed edges. It can be reused multiple times, making it a lightweight and economical perfect solution to replace traditional steel formwork.

Core advantages of film faced plywood in concrete construction

Choosing the right formwork material directly impacts your project’s cost, schedule, and the final quality of the concrete structure. Here are the key advantages of film faced plywood:

Excellent Waterproofness and Durability

The phenolic film surface creates an impermeable barrier, effectively preventing moisture from penetrating the panel. This means the board won’t swell or warp due to dampness, maintaining its structural integrity far better than standard commercial plywood.Smooth Concrete Finish

As a leading manufacturer, Plyboost ensures an extremely smooth and flat film surface. This results in a smooth, uniform concrete surface after demolding, requiring little to no additional plastering, which saves significant time and labor costs.High Reusability and Cost-Effectiveness

A high-quality film faced plywood can be reused up to 20-30 times, depending on concrete pressure and curing conditions. This high reusability significantly reduces the per-use formwork cost for a project. For projects demanding extreme durability and even more reuses, our superior red film faced plywood offers a thicker film and enhanced protection.High Strength and Light Weight

Compared to heavy steel forms, film faced plywood is much lighter, making it easier to transport and handle on-site, thereby improving construction efficiency, while its structural strength is sufficient to withstand the lateral pressure of concrete.

Film faced plywood vs. other construction panels

When selecting formwork material, understanding the properties of different panels is crucial.

Compared to Marine Plywood: While marine plywood also offers excellent moisture and water resistance, it lacks the hard surface film. This makes film faced plywood superior in resisting concrete abrasion and achieving a smoother concrete finish.

Compared to OSB and Particle Board: OSB (Oriented Strand Board) and particle board are sometimes considered due to their lower cost, but they are prone to swelling and losing strength when absorbing moisture, making them entirely unsuitable for the high-moisture, high-strength environment of concrete formwork.

How to choose the right film faced plywood for your project

Selecting the suitable film faced plywood involves considering several factors:

Film Thickness and Color: Common films are brown and black, while the red film offered by Plyboost typically represents a higher grade of durability.

Core Material: The quality of the plywood core determines its overall structural strength. For instance, film faced plywood using a birch plywood core is exceptionally strong and durable.

Required Reuse Cycles: Define your project’s requirements for formwork reusability. This will help you choose the best option between standard products and our superior red film faced plywood.

Supplier Reliability: Choosing a Chinese manufacturer like Plyboost, with a strict quality control system, ensures you receive products that meet or exceed international standards.

Plyboost: Your trusted Chinese film faced plywood manufacturer

At Plyboost, we understand the importance of quality materials for project success. Utilizing advanced production technology and stringent quality control, we provide top-quality film faced plywood to clients in China and worldwide. Our diverse product range, from standard film faced plywood to high-performance red film faced plywood, meets various needs, from residential buildings to large infrastructure projects.

Beyond concrete formwork, our product line also includes various construction and decorative panels, from UV MDF plywood to flame-retardant MDF, offering you a one-stop solution for all your panel needs.

Contact Plyboost today to get free samples and a professional quote for your next project!

Related Products

Related blogs

An Analysis of the Advantages and Disadvantages of Different Edge Treatment Methods for Melamine Plywood

Melamine plywood, a material widely used in furniture manufacturing, interior decoration, and other fields, has

Additives Used in Plywood Glue: Functions and Benefits

Additives are essential in plywood glue formulations, enhancing the performance, durability, and environmental friendliness of

Synchro Plywood: A High-Quality Composite for Realistic Wood Finishes

What is Synchro Plywood? Synchro Plywood is an innovative composite material designed to emulate the

The 5 Best Kitchen Cabinet Materials: Pros and Cons

Choosing the right material for your kitchen cabinets is essential for both style and durability.

Kitchen Cabinet Fabrication: Plywood vs. Melamine Board

Choosing the right material for your kitchen cabinets is a critical decision that impacts the

Exploring the Versatility and Strength of the OSB Board

Oriented Strand Board (OSB) is transforming the construction landscape with its remarkable versatility, strength, and

What is Furniture board?

Furniture board, as the term implies, refers to a type of engineered wood product that

Understanding and Analysis of WPC Board vs Plywood

When deciding on materials for interior work in homes or offices, two of the most