Plywood formwork is revolutionizing the construction industry as a lightweight, durable, and eco-friendly system that ensures the creation of high-quality concrete surfaces. This method involves combining specially prepared layers of plywood, providing a versatile solution for large surface coatings in construction projects. While various types of plywood materials are used worldwide, the key to achieving superior concrete results lies in the type of coating applied to the plywood surface.

Advantages of Plywood Formwork:

High-Quality Concrete Finish

Plywood formwork consistently delivers exceptional concrete cast surfaces, meeting the stringent requirements of modern construction projects.

Optimal Weight-to-Strength Ratio

Plywood’s inherent stiffness minimizes deflection, ensuring structural integrity and stability during concrete pouring.

Exceptional Durability

Plywood formwork is built to last, with resistance to wear and tear, moisture, and environmental factors, guaranteeing long-term performance.

Reusable

This formwork system can be used repeatedly across multiple projects, reducing waste and cost while enhancing sustainability.

Enhanced Panel Shear

Plywood’s cross-laminated structure results in superior panel shear compared to solid timber, ensuring robustness and reliability.

Ease of Machining and Fixing

Standard machining and fastening methods can be used, simplifying construction processes.

On-Site Handling

Plywood formwork is easy to handle, facilitating efficient on-site assembly and disassembly.

Chemical Resistance

It exhibits good chemical resistance, adding to its durability in various construction environments.

Variety of Options

Plywood formwork comes in a wide range of overlays and sizes, allowing flexibility in design and application.

Applications of Plywood Formwork:

Plywood formworks find applications in various construction scenarios, contributing to efficient and cost-effective building processes. Some of the primary application areas include:

Walls and Columns

Plywood formwork is employed in shaping walls and columns within concrete structures, accommodating diverse design requirements. It is used in framed systems, area systems, side support systems, weight framed systems, circular systems, column systems, and more.

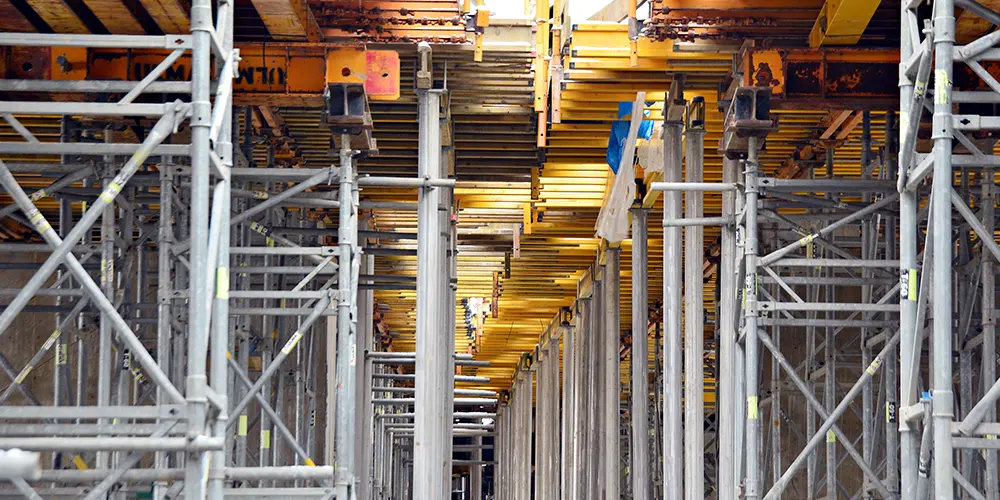

Slabs

This formwork system is extensively used for ceiling slabs, formwork for slab tables, drop beams, and other applications related to slab construction.

Infrastructural Projects

In infrastructure projects like tunnels and bridges, where continuous concrete pouring and durability are paramount, customized plywood formwork solutions are preferred. Applications include crane climbing formwork, shaft platforms, configured tunnel systems, customized steel forms, and more.

What is Film Faced Plywood:

Film faced plywood is a widely used panel in plywood formwork systems. Its surface features a film made of paper impregnated with glue/resin, offering several advantages:

Improved resistance to abrasion, moisture penetration, chemicals, insects, and fungi.

A smooth, hygienic, and easy-to-clean surface, ensuring optimal concrete quality.

Plywood formwork is a game-changer in the construction industry, offering a blend of quality, durability, and sustainability. Its versatile applications and advantages make it an indispensable choice for modern construction projects, ensuring high-quality concrete results and efficient building processes.